How to make UV halogen-free flame retardant, toughened and reinforced PA66? Super complete formula table attached!

Date:2022-02-15

Date:2022-02-15 Views:1124

Views:1124

Polyamide (PA) is a kind of engineering plastics with excellent comprehensive properties. It has the characteristics of high strength, easy processing, solvent resistance and good heat resistance. It is widely used in the fields of automobile, household appliances, electric tools and so on. It is one of the widely used engineering plastics. Although polyamide 66 (PA66) has good mechanical, processing and heat resistance properties, it still can not meet the specific application needs in practical use. It is often necessary to add flame retardant, toughening and reinforcing agent and UV aging resistant agent according to the specific use needs of downstream customers to modify PA66.

So in the process of preparing UV halogen-free flame retardant, toughened and reinforced PA66, what effect will the content of different additives have on the finished product?

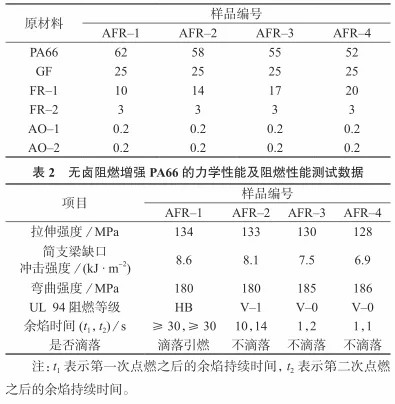

Halogen free flame retardant content

Formula of halogen-free flame retardant

With the increase of halogen-free flame retardant content, the tensile strength and notched impact strength of halogen-free flame retardant reinforced PA66 decreased, and the bending strength increased. This is mainly because the halogen-free flame retardant added is not completely dense and defect free. With the increase of the amount of halogen-free flame retardant, local defects will appear in the halogen-free flame retardant reinforced PA66 matrix, resulting in the reduction of tensile strength and notch impact strength of simply supported beam.

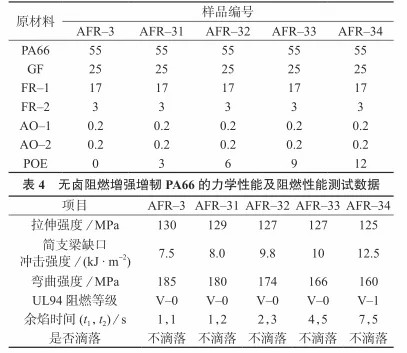

Toughening agent content

Toughening agent formula

With the increase of toughening agent content, the notch impact strength of simply supported beam of halogen-free flame retardant reinforced and toughened PA66 increases. The addition of toughening agent makes it as the stress concentration point to disperse the impact force in the matrix. Through the deformation and stress transfer absorption in the matrix, the blend system can better absorb the impact energy and have excellent toughness. At the same time, the flexural strength and tensile strength of halogen-free flame retardant reinforced and toughened PA66 decreased with the increase of toughening agent content. This is because the molecular chain of the toughener has good flexibility. When subjected to bending force or tensile force, its molecular chain migrates, resulting in the reduction of bending strength and tensile strength. However, the toughening agent is olefin polymer, which is easy to release more heat during combustion, and the combustion flame cannot be extinguished in a short time, which is contrary to the effect of flame retardant. The increase of the addition amount leads to the longer combustion time of the material, which makes the flame retardant performance of halogen-free flame retardant reinforced and toughened PA66 worse.

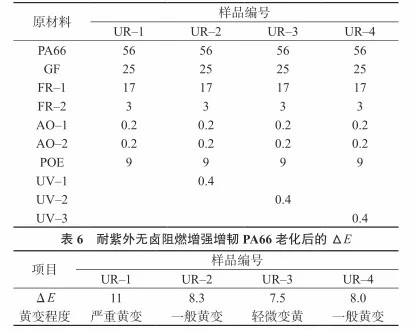

UV aging resistant additive

Formula of UV aging resistant additives

Due to the small amount of UV aging resistant additives, they have little effect on the mechanical properties and flame retardant properties of halogen-free flame retardant reinforced and toughened PA66. Adding different UV aging resistant additives can greatly improve the yellowing degree of halogen-free flame retardant reinforced and toughened PA66. However, after aging, the epitaxial initial decomposition temperature of UV halogen-free flame-retardant reinforced and toughened PA66 decreases, indicating that the group induced material produced under UV aging decomposes in advance.

Wechat scanning communication

Wechat scanning communication