Principle of reactive flame retardant and its application in epoxy resin, polyurethane, etc

Date:2022-05-24

Date:2022-05-24 Views:1239

Views:1239

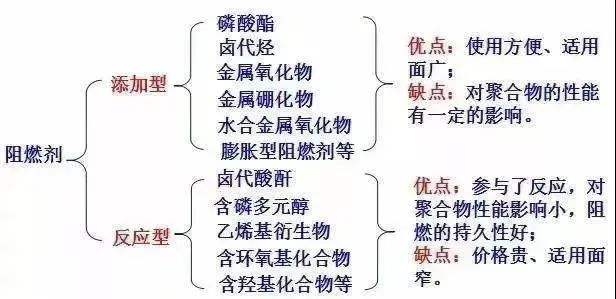

According to the differences of introduction methods, flame retardants can be divided into additive flame retardants and reactive flame retardants. Additive flame retardants are usually incorporated into polymers in a physical way, which is economical and convenient to use, but they generally have poor compatibility with polymers, need a large amount of additives to achieve better flame retardant effect, and have the defects of reducing the mechanical properties of polymer materials.

Different from the principle of additive flame retardant, reactive flame retardant can form copolymer with monomer or graft polymer, so it can make the material have lasting flame retardancy. Moreover, reactive flame retardants have little effect on the mechanical properties of polymer materials, and only a small amount of reactive flame retardants can achieve good flame retardant effect. It is a hot topic in the research of flame retardants at present. This paper mainly introduces the basic flame retardant mechanism of reactive flame retardant and its application in the fields of epoxy resin, polyurethane, cotton fabric and flame retardant paper.

Flame retardant mechanism of reactive flame retardant

The combustion process of polymer materials is a complex process with multiphase reaction, which is accompanied by both physical and chemical changes. Reactive flame retardants show different flame retardant mechanisms in different flame retardant systems, which is caused by the differences of their own components and the material characteristics of different polymers. However, generally speaking, the flame retardant mechanism of reactive flame retardants can be divided into two categories: gas camera mechanism and condensation camera mechanism.

1. Gas phase mechanism

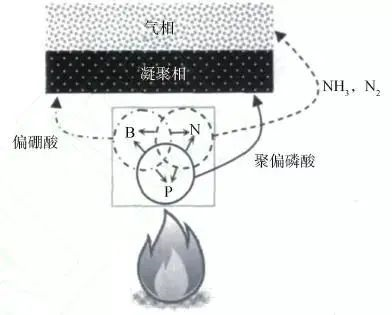

Corresponding to the combustion process, the gas-phase flame retardant mechanism of reactive flame retardants includes both physical and chemical reactions, and more is the synergy between the two. The physical effect is mainly reflected in that some reactive flame retardants can absorb the heat in the environment, decompose and release non combustible gases such as nitrogen, ammonia and carbon dioxide. These gases can usually dilute the combustible gases in the cracking place of polymer materials or the central area of flame to reduce their concentration below the combustion limit, so as to prevent the continuous combustion of materials. Sometimes some non combustible gases also have the function of heat dissipation, which can reduce the temperature of the surrounding environment.

Gas phase and condensed phase flame retardant

Chemical action is mainly reflected in the capture mechanism of free radicals. For example, some phosphorus flame retardants can release relevant free radicals in high temperature environment and react with H. and O h. conducive to combustion. In this case, the chain reaction of combustion can be prevented and the heat released by flame can be greatly reduced.

2. Condensation mechanism

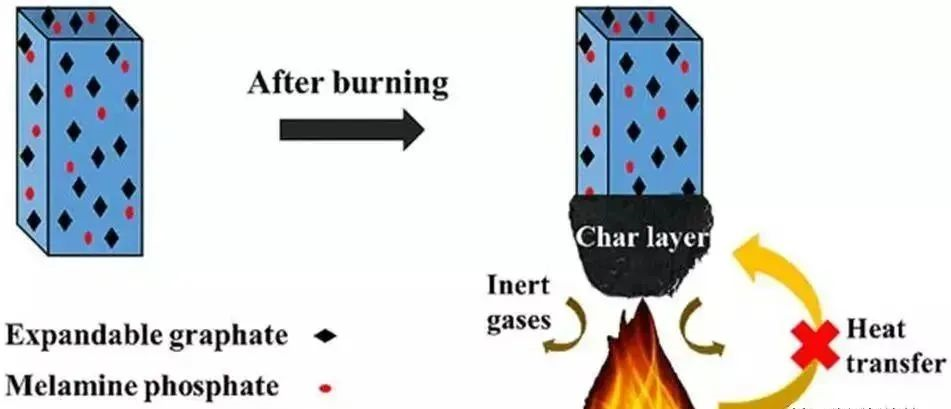

The flame retardant mechanism of reactive flame retardants has a variety of action modes in the condensed phase, and the general carbonization is the most common mode. Reactive flame retardants usually can greatly increase the carbon formation of polymers, especially oxygen-containing polymers, such as epoxy resin, cellulose and so on.

The carbon layer is generally formed in the boundary area of gas phase and condensed phase, which has a good protective effect. It can be regarded as a protective barrier to prevent the transmission of oxygen and heat in the air and achieve the effect of restraining the generation of combustible gas. Taking the application of flame retardant in cotton fabric as an example, it changes the pyrolysis reaction process of fiber macromolecular chain in the condensed phase, promotes the dehydration, crosslinking and other reactions, and gradually forms a carbon layer. In this process, the amount of carbon residue is increased and the amount of combustible gas is also reduced.

Condensed phase carbon forming flame retardant

Reactive flame retardants can not only increase carbon residue, but also promote the oxidation resistance of carbon and prevent carbon from being completely oxidized to carbon dioxide, so as to reduce the heat released by oxidation. In addition to carbonization, the action modes of reactive flame retardants in condensed phase also include free radical inhibition, the influence mechanism of molten polymer viscosity and the effect of surface coating.

Schematic diagram of flame retardant such as inhibiting free radical and carbon formation

Generally, the main function of reactive flame retardants in flame retardant materials is to generate non combustible gas during polymer combustion, dilute the concentration of combustible gas, effectively reduce the thermal effect of materials during combustion and decomposition, increase the amount of carbonization and hinder the transfer of oxygen and heat. In addition, after being treated with reactive flame retardant, the ignition temperature of some polymer materials has been greatly improved, and the flame retardant effect has been achieved.

Application of reactive flame retardants

1. Epoxy resin

Epoxy resin (EP) is a kind of organic polymer with two or more epoxy groups in its molecular structure. It has excellent mechanical properties and flexible processing technology. It can react with various types of curing agents to form polymers with excellent insulation properties and chemical stability. It is widely used in the fields of adhesives, castables and so on. However, due to the low flame retardancy of epoxy resin, it is generally necessary to modify it to meet the requirements of special process technology.

epoxy resin

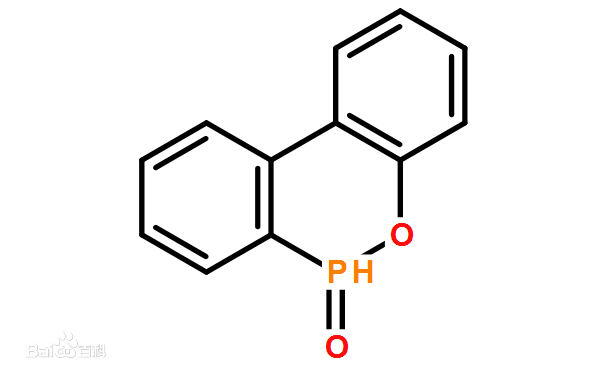

Reactive flame retardants generally improve the flame retardancy of epoxy resin by introducing groups containing flame retardant elements such as phosphorus and nitrogen into the epoxy resin system through chemical modification. The epoxy resin prepared in this way not only shows excellent flame retardant performance, but also retains the original mechanical properties of the resin to a great extent. At present, the application of reactive flame retardants in epoxy resin is mainly phosphorus and phosphorus nitrogen synergistic flame retardants. DOPO is a compound containing phosphorus heterophenanthrene ring, which has good thermal stability. The P-H bond contained in its structure can react with many unsaturated groups to produce a variety of derivatives, and most of them have good flame retardant effect.

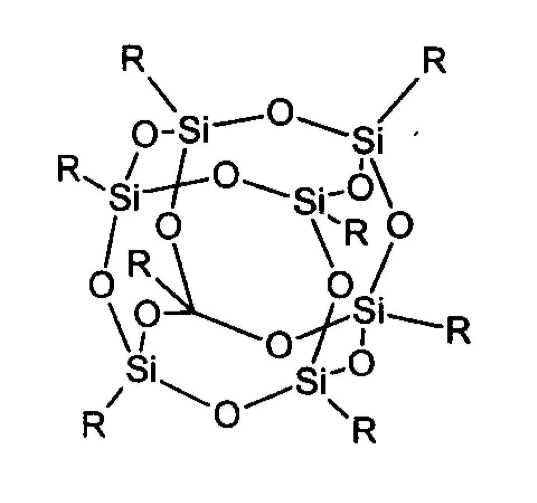

Polyhedral oligomeric silsesquioxane (POSS) is a kind of organic-inorganic hybrid nano materials with cage structure. Poss not only has an inorganic core with - Si-O-Si - as the skeleton, but also can be designed to replace the shell. The more common shell designs are organic groups and their derivatives. Poss can be grafted onto some polymers through the reaction between its organic shell and reaction end groups. The results show that poss has good dispersion in epoxy resin materials, and the epoxy resin prepared after introduction has excellent flame retardant properties.

Cage poss

However, in the process of synthesizing reactive flame retardants, there are not only complex chemical reactions, but also the use of organic solvents and toxic catalysts is difficult to avoid, which not only brings a certain burden to the environment, but also threatens human health. For example, phosphoamines are often used to improve the fire resistance of polymers, which can be synthesized from chlorophosphates by nucleophilic substitution reaction. However, this reaction is accompanied by the release of dangerous phosphorus halide and chlorhydrides.

In recent years, the use of renewable resources to prepare fireproof epoxy system has been widely recognized. Due to the overwhelming market share of bisphenol A epoxy resin, the synthesis of high-efficiency flame retardant using renewable resources to improve its fire resistance has always been an interesting topic.

2. Polyurethane

Polyurethane (PU) is a polymer composed of organic units connected by carbamate. It has many excellent properties, such as noise resistance, heat insulation, wear resistance and so on. Without flame retardant treatment, the limiting oxygen index (LOI) of polyurethane material is about 18%, which is easy to burn and release a lot of heat and toxic gases harmful to human body. At present, polyurethane reactive flame retardants generally introduce flame retardant groups into the molecular structure of polyurethane through grafting reaction, so as to improve the flame retardant effect and thermal stability of polyurethane materials in high temperature environment.

Flame retardant polyurethane foam

n the flame retardant modification of polyurethane materials, phosphorus containing flame retardants are most used, which not only have good flame retardant effect, but also low smoke and environmental protection. The principle is to introduce phosphorus into the structure of polyurethane materials in the form of chemical bonds such as P-O or P-C bonds. These covalent bonds have large bond energy and strong stability.

Nitrogen containing reactive flame retardant polyurethane materials generally introduce melamine groups into the polyurethane structure in the form of covalent bonds. Melamine is a stable crystalline compound containing 67% nitrogen atoms. It will sublimate when the temperature reaches 350 ℃, which can absorb a large amount of energy and reduce the surrounding ambient temperature. And at a higher temperature, melamine will decompose to produce nitrogen and form a thermally stable condensate.

Compared with the introduction of a single flame retardant element, the reactive flame retardant with two or more flame retardant elements has better flame retardant effect and thermal stability.

3. Cotton fabric

Cotton fabric is widely used in clothing and decoration industry because of its comfort and air permeability. However, its thermal stability is poor and may cause fire in daily life. Therefore, it is very necessary to modify cotton fabric to obtain flame retardancy and improve thermal stability.

阻燃织物

A large number of studies have shown that adding flame retardant to cotton fiber is a simple and effective method to reduce its flammability. Most commercial flame retardant chemicals are halogen-based, but halogen-based flame retardants will release a large number of harmful gases during combustion, and lead to serious health and environmental problems. Therefore, at this stage, the search for more efficient, synergistic and environmentally friendly flame retardants has gradually become the focus of research.

At present, the application of reactive flame retardants in cotton fabric is mainly phosphorus flame retardants and phosphorus nitrogen synergistic flame retardants. Phosphorus usually exists in cellulose macromolecules in the form of p-o-c covalent bond, which can greatly improve the compatibility between cotton fabric and flame retardant, and has high use efficiency.

In addition, a new synergistic flame retardant (DOPO PIP SI) containing phosphorus, nitrogen and silicon was prepared from DOPO, chloromethyltrimethoxysilane and piperazine and effectively applied to cotton fabric. The cotton fabric treated with the flame retardant showed good flame retardancy. Through the vertical flammability test, a low carbon length of 12.2cm was obtained, the LOI value could reach 27.6%, and its tensile strength was also improved.

4. Flame retardant paper

Due to the advantages of light weight and low cost, paper products are widely used in packaging, construction, decoration, agriculture and commodity industries. However, most of the paper is usually made of fiber. Due to its flammable characteristics, it is often easy to cause fire, resulting in great economic losses. Therefore, giving paper excellent flame retardancy is of great significance to reduce the amount of fire and expand the application range of paper products.

阻燃纸

In general, paper flame retardants will not only have an important impact on the flame retardancy of paper, but also have a great impact on its mechanical properties. Both additive and reactive flame retardants can be used in the preparation of flame retardant paper. However, additive flame retardants usually only need to be added to the pulp, or use physical methods such as coating and impregnation to treat the paper surface, so the durability of the flame retardant paper is poor.

Reactive flame retardants can generally graft with the fiber components in the paper to make it a part of the paper. The flame retardant paper prepared in this way not only has long-term and stable flame retardant effect, but also its mechanical properties are relatively less affected.

In addition to the direct application of reactive flame retardants to paper, flame retardant fibers can be prepared by using flame retardants, and then the corresponding flame retardant paper can be copied through flame retardant fibers, which is also a method for preparing flame retardant paper.

At present, reactive flame retardants are less used in paper products, mainly phosphorus containing flame retardants. However, because reactive flame retardants have the advantages of high efficiency and environmental protection, they have a development prospect in the application field of flame retardant paper.

To sum up, reactive flame retardants can be introduced into polymer materials by chemical reaction. Compared with additive flame retardants, reactive flame retardants have the advantages of low toxicity, environmental protection, low amount and high efficiency, and will not have a great impact on the mechanical properties of materials. They are more and more welcomed by the market. However, due to the constraints of process equipment and production mode, reactive flame retardants also have the limitations of high preparation cost and difficult mass production. The key to solve the problem is how to use relatively cheap raw materials for research and development and gradually explore a set of mature and perfect industrial production methods.

Reference: principle, application and research progress of reactive flame retardants, network data.

Wechat scanning communication

Wechat scanning communication